Blog

2025 Top 5 Car Recycling Parts: Sustainable Solutions for Eco-Friendly Vehicles

The automotive industry is undergoing a transformative shift towards sustainability, with car recycling parts playing a crucial role in this evolution. As reported by the Automotive Recyclers Association, approximately 95% of a vehicle's components can be recycled, contributing significantly to reducing waste and minimizing the environmental impact of automotive manufacturing. The demand for eco-friendly vehicles has surged, with a recent study indicating that electric vehicle sales are expected to reach 30% of total automotive sales by 2025, making sustainable practices more vital than ever.

Incorporating recycled parts not only narrows resource consumption but also supports a circular economy, enabling the reuse of valuable materials such as metals, plastics, and rubber. Data from the International Council on Clean Transportation highlights that using recycled materials can lower carbon emissions by over 20%. As we look ahead to 2025, the focus on car recycling parts will be instrumental in aiding automakers to meet stringent regulatory requirements and consumer expectations regarding sustainability. Embracing innovative recycling technologies and strategies will be essential for paving the way for a greener, more sustainable automotive future.

Innovative Technologies in Car Parts Recycling for 2025

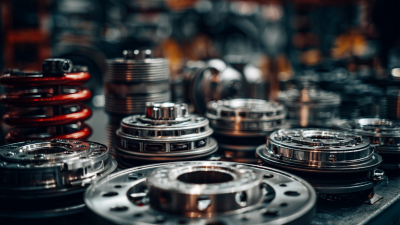

As we approach 2025, the automotive industry is witnessing transformative changes in car parts recycling, driven by innovative technologies aimed at sustainability. Advanced sorting and processing technologies are emerging, enabling recyclers to efficiently extract valuable materials from end-of-life vehicles. Automation and artificial intelligence are playing critical roles in enhancing accuracy and reducing labor costs, facilitating the recovery of metals, plastics, and rubber components in a more streamlined manner.

Moreover, emerging techniques like hydrometallurgical processes and bioleaching are gaining traction, allowing for the extraction of rare metals from car parts with minimal environmental impact. These methods not only reduce the carbon footprint associated with traditional recycling but also promote a circular economy where materials can be reused indefinitely. As manufacturers increasingly prioritize eco-friendly practices, the synergy between technology and sustainability will shape the future of car recycling, making it an essential aspect of automotive production and waste management by 2025.

The Role of Automotive Metals in Sustainable Vehicle Production

The automotive industry has witnessed a profound shift towards sustainability, especially with the increasing importance of automotive metals in vehicle production. These metals are not only essential for the structural integrity and performance of vehicles, but they also play a crucial role in enabling efficient recycling practices. As the demand for electric vehicles (EVs) rises, the focus on recovering metals from used components, particularly from power batteries, becomes imperative. Effective recycling not only supports the green economy but also mitigates the environmental impact of mining and material extraction.

Moreover, the global shift towards renewable energy sources, such as solar and wind, necessitates a robust infrastructure that relies on both recycled and sustainably sourced metals. The mining sector, estimated to reach a market size of $1.5 trillion in 2023, is under increasing pressure to embrace sustainable practices. This evolution underscores the significance of developing advanced recycling technologies that can enhance the circular economy within the automotive sector, ensuring that valuable materials are reused and emissions are minimized, thereby contributing to a greener future for all.

Eco-Friendly Plastic Solutions for Car Manufacturing in 2025

As the automotive industry shifts towards more sustainable practices, eco-friendly plastic solutions are playing a crucial role in car manufacturing by 2025. The introduction of bioplastics, derived from renewable resources, significantly reduces the carbon footprint associated with traditional petroleum-based plastics. These innovative materials not only provide the necessary durability for automotive components but also enhance recyclability, making them an attractive choice for manufacturers who prioritize environmental responsibility.

In addition to bioplastics, advancements in recycled plastics are essential for promoting sustainability in vehicle production. By incorporating post-consumer recycled plastics into their designs, automotive manufacturers can minimize waste and decrease reliance on virgin materials. This closed-loop approach not only conserves natural resources but also supports the circular economy, wherein products are designed for reuse and recycling. The integration of these eco-friendly plastic solutions is set to revolutionize the industry, aligning with the growing demand for sustainable vehicles in an increasingly eco-conscious market.

2025 Top 5 Car Recycling Parts: Sustainable Solutions for Eco-Friendly Vehicles

| Part Component | Material Type | Recycling Rate (%) | Environmental Impact | Sustainability Score (out of 10) |

|---|---|---|---|---|

| Bumpers | Recycled Plastic | 90 | Reduced landfill waste | 8 |

| Fenders | Composite Materials | 85 | Lower carbon footprint | 7 |

| Interior Panels | Biodegradable Plastics | 80 | Less environmental pollution | 9 |

| Wiring Harnesses | Recycled Copper | 95 | Conserves natural resources | 9 |

| Tires | Recycled Rubber | 75 | Energy-efficient recycling | 7 |

The Future of Tire Recycling: From Waste to Resource

The future of tire recycling presents a transformative approach to waste management, converting what was once considered a burden into a valuable resource. As the automotive industry pivots towards sustainability, innovative recycling technologies are emerging to tackle the challenge posed by the millions of discarded tires each year. Advanced processes, such as cryogenic grinding and pyrolysis, are being developed to break down tires into reusable materials, including rubber granules, steel, and carbon black. These materials can then be repurposed in various applications, from construction to new tire manufacturing.

Moreover, tire recycling not only reduces landfill waste but also mitigates the environmental impact associated with traditional disposal methods. By adopting a circular economy model, tire manufacturers and consumers can significantly decrease the carbon footprint associated with new tire production. Collaborative efforts between governments, businesses, and consumers are essential to create effective recycling programs and raise awareness of the environmental benefits. As the tire recycling industry evolves, it lays the groundwork for sustainable practices that benefit both the economy and the environment, paving the way for eco-friendly vehicles of the future.

2025 Top 5 Car Recycling Parts: Sustainable Solutions

This chart shows the estimated recycling rates of various car parts in 2025, highlighting the importance of sustainable solutions in the automotive industry.

Revitalizing Batteries: Sustainable Practices in Electric Vehicle Parts Recycling

The sustainability of electric vehicle (EV) batteries is increasingly significant as the shift towards eco-friendly vehicles intensifies. A recent analysis highlights that at the end of their operational lifespan, typically 10-15 years, EV lithium-ion batteries can retain approximately 70-80% of their original capacity. This residual capacity presents substantial opportunities for repurposing and recycling, contributing to a circular economy in the automotive sector.

As global demand for lithium-ion batteries escalates, the necessity for advanced recycling technologies becomes ever more critical. Reports indicate that recycling not only mitigates environmental impacts but also enhances resource recovery. For instance, improvements in recycling processes can lead to a significant reduction in the need for raw material extraction, which is crucial given that China produces nearly two-thirds of the world's EV batteries. Sustainable practices in the recycling of retired EV batteries involve strategic decisions that weigh both economic feasibility and environmental benefits, thereby promoting a resilient framework for energy transition and material efficiency within the EV supply chain.

Related Posts

-

Unlocking Sustainability: How Car Recycling Parts Contribute to a Greener Future

-

Innovating Auto Recycling Strategies at the 138th Canton Fair 2025 Insights and Industry Data

-

10 Essential Junk Car Parts You Need to Know for Your DIY Auto Repairs

-

Top 10 Junkyard Parts for Cost-Effective Car Repairs: Save Up to 70% on Auto Parts!

-

Exploring the Evolution of Automotive Body Parts: From Classic Designs to Modern Innovations

-

The Ultimate Guide to Choosing Quality Car Auto Parts for Your Vehicle's Long Life

Logel’s Auto Parts

116 Bridge St East

Kitchener, Ontario

N2K 1J6

Phone: 519-745-4751

Toll Free: 1-800-818-9118

Hours 8:00-5:00 Monday to Friday

At Logel’s Auto Parts, we serve a range of communities in Southern Ontario, including: