Blog

Exploring the Evolution of Automotive Body Parts: From Classic Designs to Modern Innovations

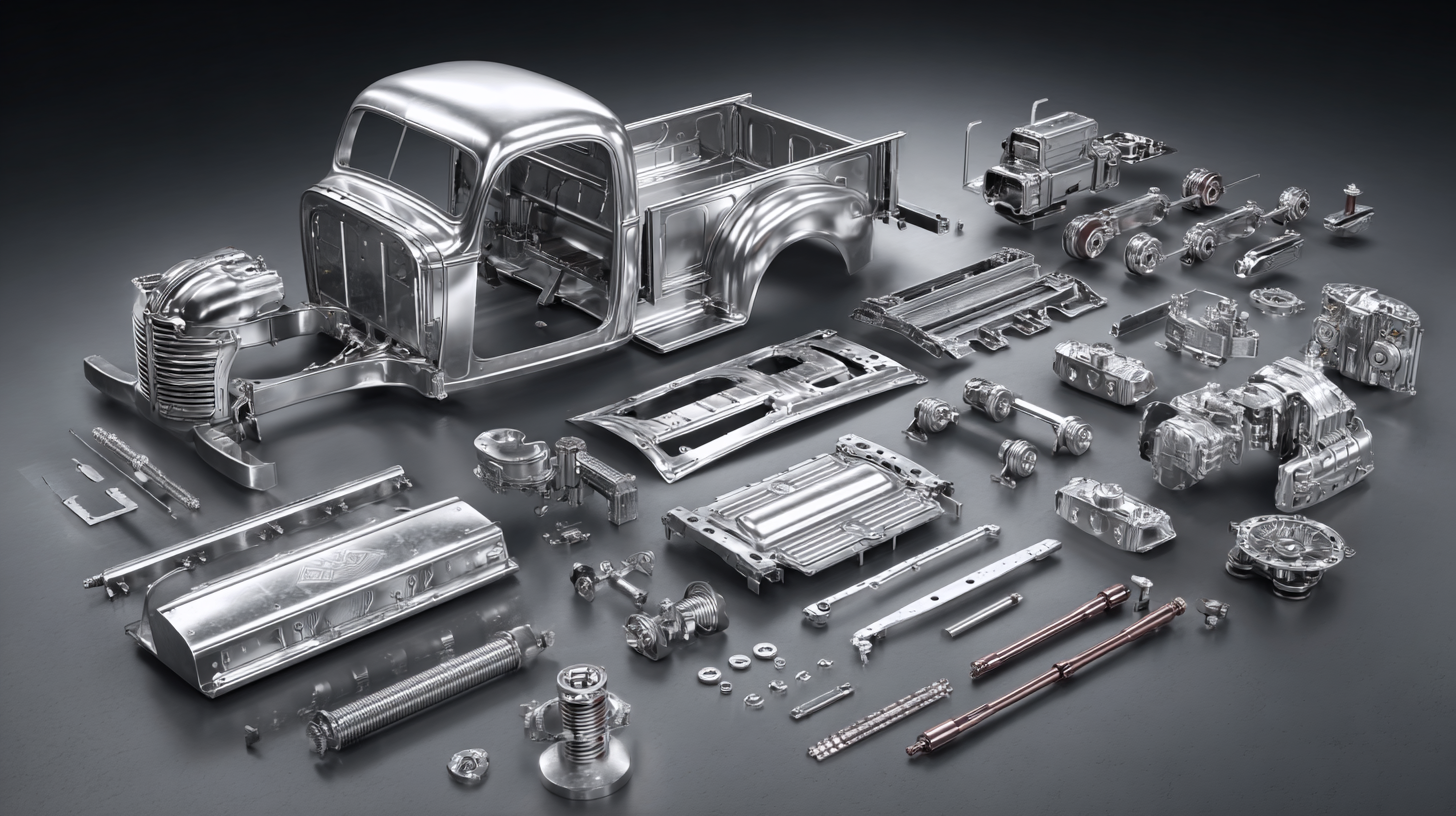

The evolution of automotive body parts has significantly shaped the automotive industry, reflecting advancements in technology, design aesthetics, and consumer preferences. According to a recent report by MarketsandMarkets, the global automotive body parts market is projected to reach USD 101.6 billion by 2025, growing at a CAGR of 4.8% from 2020 to 2025. This growth underscores a shift from traditional heavy metal components to lightweight materials, such as aluminum and carbon fiber, which enhance fuel efficiency and performance. Furthermore, innovations like advanced manufacturing techniques including 3D printing and the rise of electric vehicles are driving the development of smart body parts that integrate features like sensors and adaptive designs.

As we explore the journey from classic designs to modern innovations, it becomes clear that automotive body parts are not merely structural components but are essential for enhancing safety, efficiency, and overall driving experience.

Understanding the Historical Context of Automotive Body Parts

The evolution of automotive body parts has been a fascinating journey shaped by technological advancements and shifting consumer preferences. Historically, the materials used for vehicle exteriors have transitioned from wood and steel in early car designs to modern lightweight composites and aluminum. According to a 2022 report by the International Automotive Engineering Association, the adoption of aluminum body panels has led to a 30% reduction in vehicle weight, enhancing fuel efficiency and performance. This shift not only reflects advancements in manufacturing processes but also a growing awareness of environmental concerns.

In the early days of the automotive industry, manufacturers focused primarily on robust designs with limited emphasis on aerodynamics or aesthetics. However, as cars became more mainstream, stylistic elements gained importance. By the mid-20th century, aerodynamic design began to play a crucial role, with the introduction of features like curved body shapes to reduce drag. A 2021 market analysis by Automotive Trends indicated that streamlined designs can improve fuel efficiency by up to 10%. Today, innovations such as 3D printing and smart materials are further revolutionizing body part production, allowing for customization and enhanced safety features, marking a significant departure from the rigid designs of the past.

Identifying Key Design Innovations in Classic Automotive Body Structures

The evolution of automotive body structures has witnessed significant innovations, particularly when examining key design elements found in classic vehicles. Classic car designs, such as the Ford Model T or the Chevrolet Bel Air, featured a focus on simplicity and functionality. According to a report from AutoIndustry Insights, classic steel constructions provided not only structural integrity but also cost-effectiveness during production, with costs averaging around $250 per unit at the time. These materials and designs were pivotal in making automobiles accessible to the masses.

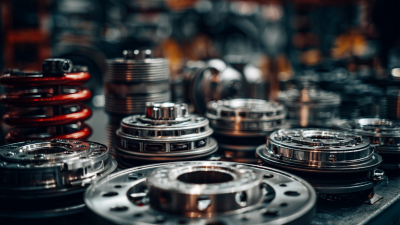

As the industry progressed, innovations emerged that transformed body design. The introduction of unibody construction in the 1960s significantly altered the architecture of vehicles, integrating the body and chassis into a single piece, which enhanced safety and reduced weight. A 2021 survey by the Society of Automotive Engineers revealed that modern vehicles utilize up to 59% high-strength steel and aluminum in their construction, improving performance and fuel efficiency by over 30%. This shift illustrates how advancements in materials technology have driven the evolution of automotive design from the robustness of classic models to the sleek, efficient bodies of today’s vehicles.

Examining Modern Materials Used in Automotive Body Manufacturing

The evolution of automotive body parts has been significantly influenced by the growing demand for electric vehicles (EVs), which rely heavily on batteries for power. This reliance on batteries not only enhances vehicle performance but also adds considerable weight, necessitating a focus on materials that optimize range and efficiency. In this context, automakers have increasingly turned to lightweight materials to balance the mass of battery systems, ensuring that vehicles remain agile while accommodating the demands of electric propulsion.

Advanced High-Strength Steel (AHSS) has emerged as a pivotal material in the production of modern automotive bodies. It allows manufacturers to create vehicles that are not only lighter but also stronger, contributing to improved safety without compromising structural integrity. The innovations in manufacturing processes showcased during events like E-Forest Tech Day highlight how collaboration among manufacturers and technology partners is driving forward intelligent production techniques. These advancements not only foster the development of vehicles that comply with modern safety and efficiency standards but also aim to significantly reduce emissions, reflecting a holistic approach to sustainability within the automotive industry.

Analyzing the Influence of Aerodynamics on Body Part Design

Aerodynamics plays a crucial role in the design of automotive body parts, influencing not only aesthetics but also functionality and performance. In recent years, automotive manufacturers have increasingly prioritized aerodynamic efficiency to enhance fuel economy and reduce emissions. According to a 2021 report by the International Council on Clean Transportation (ICCT), improvements in aerodynamic designs have led to a 20% reduction in drag for new electric vehicles, significantly impacting their range and performance. For instance, the Tesla Model S features a drag coefficient of just 0.24, showcasing how advanced aerodynamics can translate into practical benefits for consumers.

One of the most notable innovations in automotive body design is the integration of computational fluid dynamics (CFD) in the development process. This technology enables engineers to simulate airflow around a vehicle, allowing for adjustments that optimize aerodynamics before physical prototypes are built. A study from the Society of Automotive Engineers (SAE) highlighted that effective use of CFD can reduce development time by up to 30%, streamlining the path from concept to market. As the industry continues to evolve, the influence of aerodynamics on body part design will remain a pivotal factor, driving both creative design solutions and advancements in vehicle technology.

Evolution of Automotive Body Parts: Influence of Aerodynamics

This chart illustrates the average drag coefficient (Cd) of automotive body designs from classic to modern vehicles. The reduction in drag coefficient reflects significant advancements in aerodynamics that enhance fuel efficiency and performance in modern automotive design.

Exploring Future Trends in Automotive Body Parts and Technologies

The automotive industry is on the cusp of significant transformation, particularly in the realm of body parts and technologies. According to a recent report by Statista, the global automotive body parts market was valued at approximately $220 billion in 2022, and is projected to reach around $300 billion by 2030, reflecting a compound annual growth rate (CAGR) of over 4%. This growth is largely driven by advancements in materials science, with lightweight composites and high-strength steel becoming increasingly prevalent. These materials not only enhance vehicle performance and fuel efficiency but also contribute to improved safety standards due to their resilience.

As we look toward the future, innovations such as 3D printing and smart materials are set to revolutionize vehicle design and manufacturing processes. Research from the McKinsey Global Institute indicates that the integration of 3D printing in automotive production could reduce costs by up to 25% while significantly shortening lead times. Furthermore, technologies like self-healing materials, which can repair minor damages autonomously, are becoming a reality, poised to extend the lifecycle of automotive body parts dramatically. As manufacturers adapt to these trends, they will need to balance efficiency with consumer demand for sustainability, resulting in a rapidly evolving landscape for automotive body parts and technologies.

Exploring the Evolution of Automotive Body Parts: From Classic Designs to Modern Innovations - Exploring Future Trends in Automotive Body Parts and Technologies

| Year | Body Part Type | Material Used | Innovations | Future Trends |

|---|---|---|---|---|

| 1950 | Hoods | Steel | Curved designs for aerodynamics | Lightweight alloys |

| 1980 | Bumpers | Plastic | Impact resistance | Smart bumpers with sensors |

| 2000 | Doors | Aluminum | Reinforced structures | Self-closing capabilities |

| 2020 | Fenders | Carbon Fiber | Weight reduction | Recyclable materials |

| 2025 | Hoods | Biocomposite | Sustainability focus | Integrated solar panels |

Related Posts

-

Why Automotive Body Parts Are Crucial for Vehicle Safety: Understanding the Industry Standards and Impact

-

The Ultimate Guide to Choosing Quality Car Auto Parts for Your Vehicle's Long Life

-

Understanding the Importance of Quality Auto Parts for Vehicle Safety and Performance

-

Essential Motor Parts: Your Ultimate Guide to Upgrading Vehicle Performance

-

Innovating Auto Recycling Strategies at the 138th Canton Fair 2025 Insights and Industry Data

-

Unlocking Opportunities in the Junk Car Parts Industry at the 138th China Import and Export Fair in 2025

Logel’s Auto Parts

116 Bridge St East

Kitchener, Ontario

N2K 1J6

Phone: 519-745-4751

Toll Free: 1-800-818-9118

Hours 8:00-5:00 Monday to Friday

At Logel’s Auto Parts, we serve a range of communities in Southern Ontario, including: